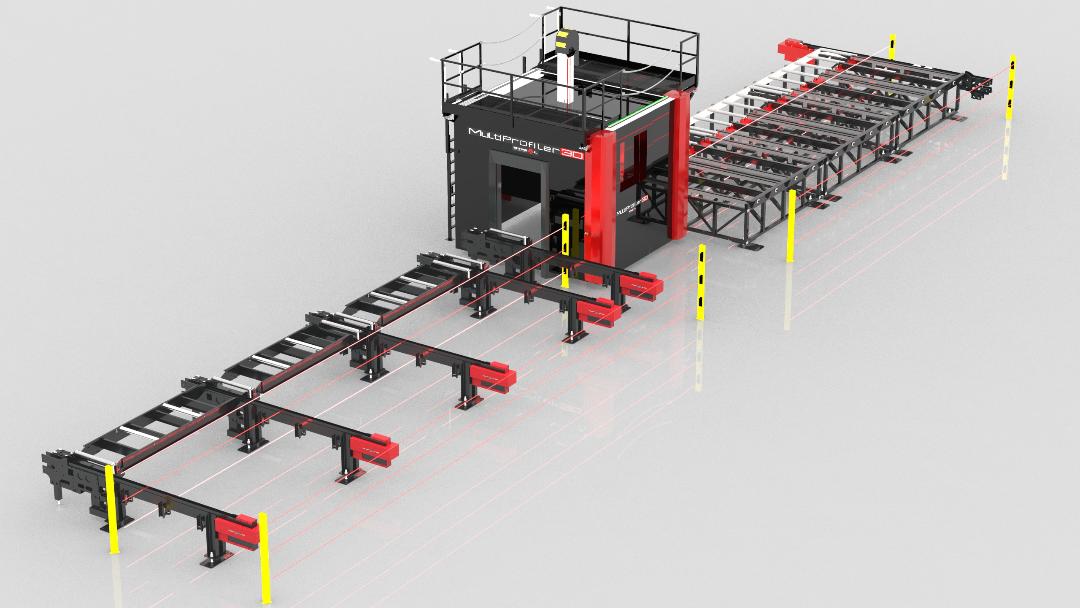

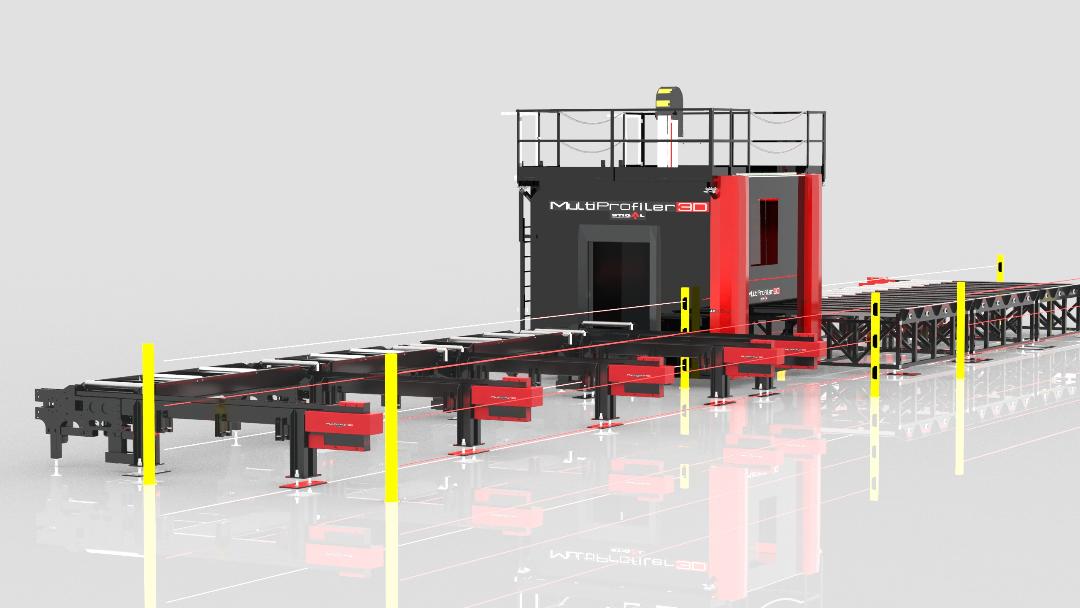

The purchase of an automated line for cutting steel profiles is another investment of the Szczecin Shipyard “Wulkan”.

Thanks to the investment in a modern 3D plasma cutting machine, we offer a service of cutting profiles as well as open and closed sections. The most modern technical solutions enable cutting out complex shapes as well as cutting at a fixed angle.

Advantages of the automatic plasma cutting line:

- Possibility to perform many technological operations on one production socket.

- High measuring accuracy and very good quality of the cut edges.

- Minimal thermal deformation of the cut elements (very narrow heat-affected zone).

- High cutting performance.

- Reduction of material costs and logistics operations.

Benefits for the client:

- Guarantee of quality.

- High measuring accuracy.

- Very good quality of the cut edges.

- The speed of the service.

General technical specification:

- Plasma cutting of flat bars in the thickness range of 50×5 mm to 300×30 mm.

- Plasma cutting of HP 60 to HP 340 bulb flat bars.

- Plasma cutting of 50x50x5 mm equal angles to 250x250x25 mm.

- Plasma cutting of unequal angles 75x50x5 / 6 mm up to approx. 600×200 mm.

- Plasma cutting of HEB beams in the range HEB 100 to HEB 600 and other H profiles in a similar range.

- Plasma cutting of T-bars in the range from 60x60x7 to 120x120x13.

- Plasma cutting of closed, square and rectangular profiles with a side length of up to 400 mm (cutting limited to 3 walls, without automatic profile rotation – cutting the fourth wall possible after manual profile rotation).

- The length of the automatic profile loading table is 12 m + a station with a plasma torch on a Multi3D 5-axis head.

- Automatic station for unloading finished parts.

- Head for automatic marking of material positions – quick ink marking (quick ink marking – applying any descriptions facilitating the identification of elements, assembly notes, etc.)

- Tooling for automatic tracing of control bending lines and reference lines – plasma marking and tracing – precise and durable and applying points, lines and alphanumeric characters, which will still be visible after the application of the paint coating by spraying or galvanizing – e.g. element name, drawing number, other markings).

- The control system is equipped with MACRO figures enabling the execution of most of the current jams without the need to prepare programs in the technology office.

- Technological software enabling the preparation of cutting programs for the machine. Enabling the laying of several cutting programs on profiles with commercial lengths, e.g. 12 meters.